SLG solution

A revolution in the conditioning, treatment and reuse of municipal and industrial sludge

Unparalleled economic and environmental performance

SLG is a breakthrough technology that significantly optimizes the conditioning of municipal and industrial sludge by modifying its physico-chemical and rheological properties. The solution improves the overall performance of Waste Water Treatment Plants, reduces sludge volumes and lowers treatment plant operating costs.

SLG uses air and energy exchange to modify the structure of the sludge and to create an emulsion. More of the bound water is released and SLG sludge floats. Adding polymers completes the flocculation optimization phase of “SLG sludge”, which is then treated by the dewatering equipment already in use in the plant. During installation of the SLG solution, Orège adjusts the operating settings of the dewatering equipment to adapt them to the modified physico-chemical and rheological properties of “SLG sludge” to ensure optimal performance.

SLG is a compact technology that can be easily integrated with existing thickening & dewatering equipment at Waste Water Treatment Plants, significantly improving thickening and dewatering performance without affecting everyday operations.

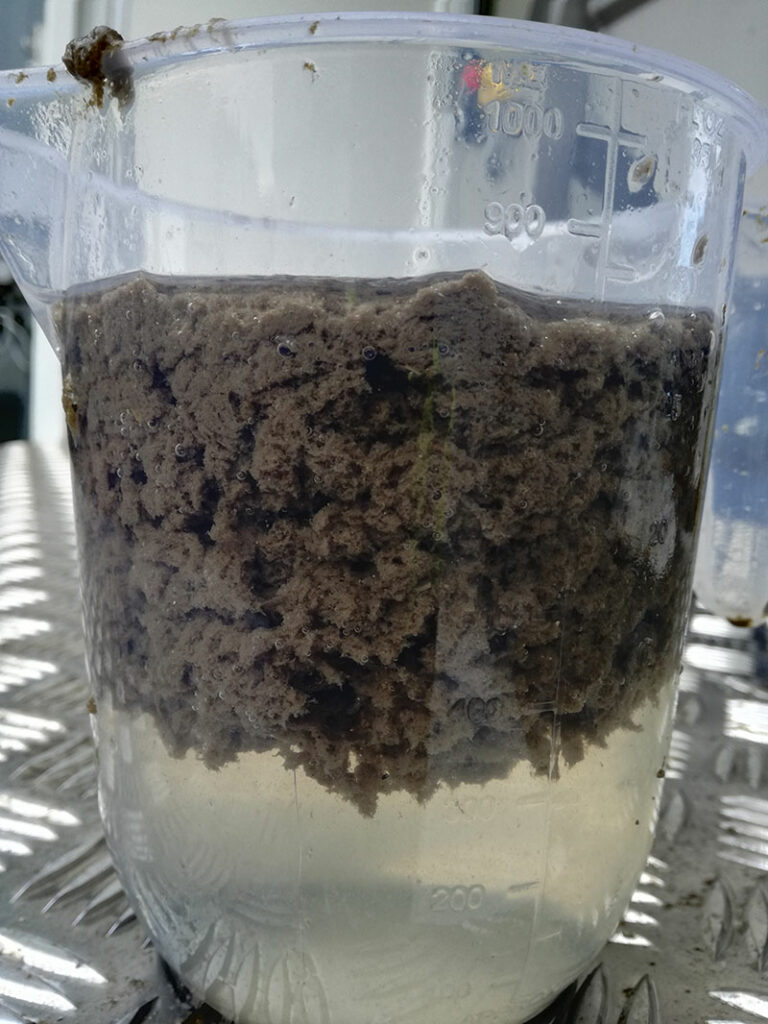

Flotation of the SLG conditioned sludge

Main Advantages

- Reduce thickened sludge and / or cake volume

- Reduce carbon footprint and GHG emissions

- Reduce polymer consumption

- Improve filtrate quality

- Improve rheology and pumpability of sludge

Addtional Benefits

- Increase existing equipment treatment capacity

- Reduce odours and corrosive gas emissions during sludge storage.

- Reduce energy consumption

Sludge Recovery

- Improve the agricultural recovery of sludge: land application and composting

- Improve anaerobic digestion performance

- Improve digester hydraulic retention time and boost biogas production

- Develop energy recovery from sludge

SLG skid

For more information click here: